SCC designs and manufactures customized conveyor belts of any kind and shape, for different types of application, ensuring high quality and reliability standards that have always distinguished his products. The conveyor belts are used in production plants for the transportation of any kind of material, from the movement of finished products to the evacuation of production scraps, with the consequent increase of productivity and operating costs reduction.

Our production, reliable and efficient, offers different versions of conveyor belts, according to the material to be conveyed, with a wide choice of options for the transport of all kinds of materials, even for production processes that require a high removal rate or handling.

Moreover, where the particular production needs require it, anti-wear materials can be used and / or customized solutions can be implemented to ensure durability of the conveyor over time.

Our production, reliable and efficient, offers different versions of conveyor belts, according to the material to be conveyed, with a wide choice of options for the transport of all kinds of materials, even for production processes that require a high removal rate or handling.

Moreover, where the particular production needs require it, anti-wear materials can be used and / or customized solutions can be implemented to ensure durability of the conveyor over time.

Types

Conveyor

SCC produces conveyors for use in a wide range of applications, providing its experience and technologies to support the customer to define the optimal solution for every single application required. Conveyors can be built in different types and sizes.

They can be manufactured not only in iron (simple or anti-wear) and in stainless steel, but also, upon request, in other materials, designed to withstand extreme mechanical and thermal conditions without deformation or performance loss.

The conveyors are all equipped with suitable accident prevention protections fully compliant with current regulations, so that no moving parts of the conveyor come into contact with the operator.

Metal chains

SCC manufactures metal chains (shutters) with different pitches, both perforated and blind, with or without lateral wings, having dimensions (width and length) upon specific customer request. The chains (shutters) can be supplied as single pieces or finished belts. Information on the available solutions and their characteristics are summarized in the table

| PASSO mm |

RICCIOLO CENTRATO | RICCIOLO NASCOSTO | CIECA | FORATA | ALETTA PIEGATA | ALETTA SALDATA | ALETTA CIANFRINATA | SEZIONE PERNO mm |

SEZIONE RULLO CATENA mm |

|---|---|---|---|---|---|---|---|---|---|

| 31.75 | X | X | X | X | 5 | 19 | |||

| 50 | X | X | X | X | X | X | 10 | 31 | |

| 63 | X | X | X | X | X | X | 12 | 40 | |

| 75 | X | X | X | X | X | X | 12 | 40 | |

| 100 | X | X | X | X | X | X | 12 | 40 | |

| 125 | X | X | X | X | X | X | 12 | 40 | |

| The shutters are available in iron or stainless steel material | |||||||||

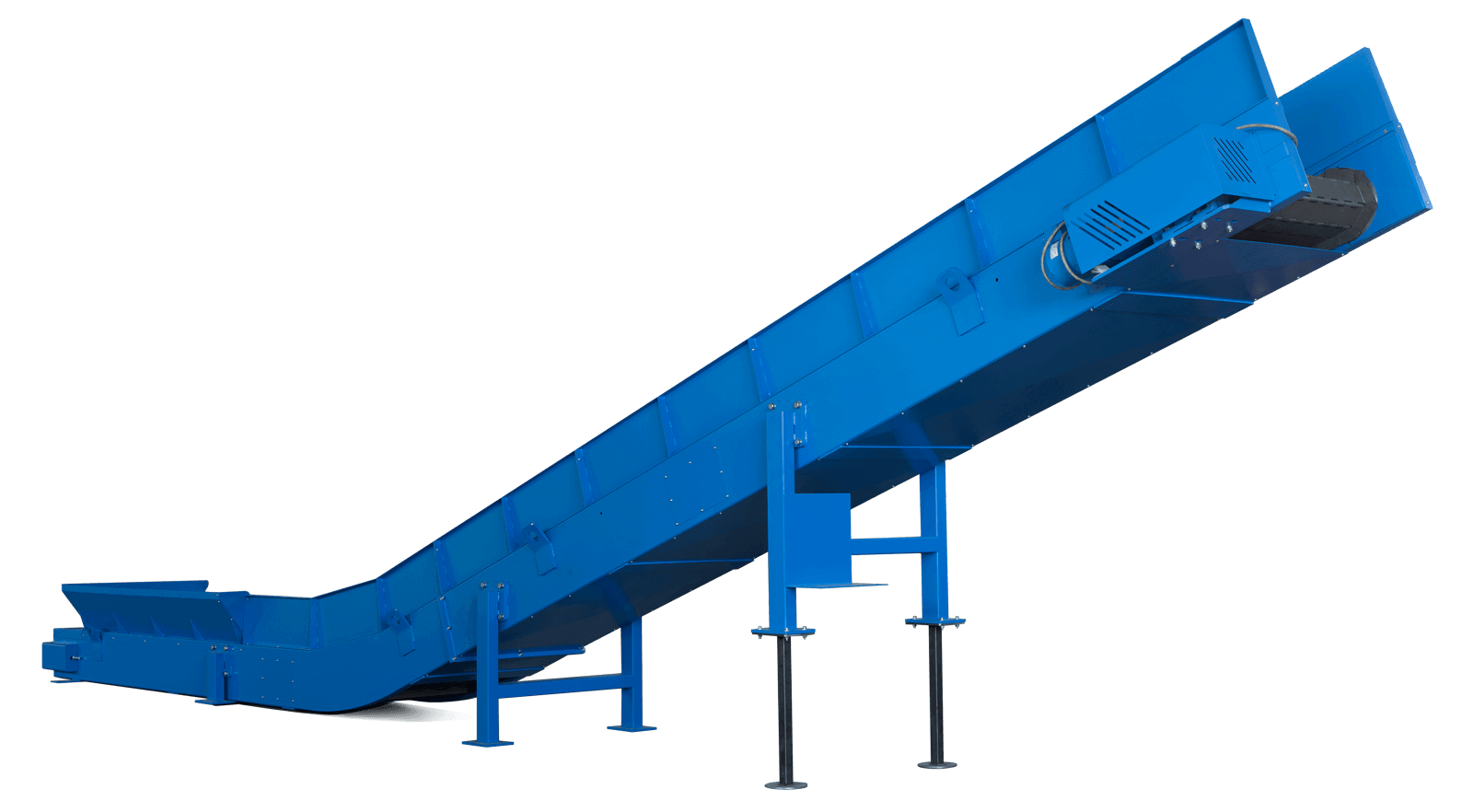

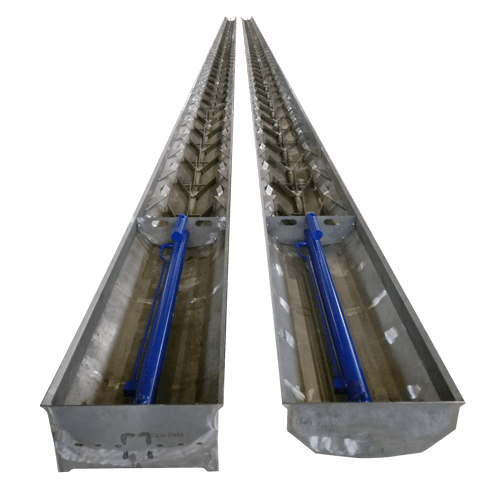

Hinge belt conveyor

Used for the convey of many different materials, both finished products and the manufacturing process scraps.

Among the latter, it is typically used in the removal of aluminum chips, ferrous and non-ferrous particles, coil or long curl type, and other wet or incandescent waste material.

The materials are moved by means of a metal roller shutter with side containment wings.

This type of conveyor is suitable for several applications available through the use of shutters with a series of different pitches.

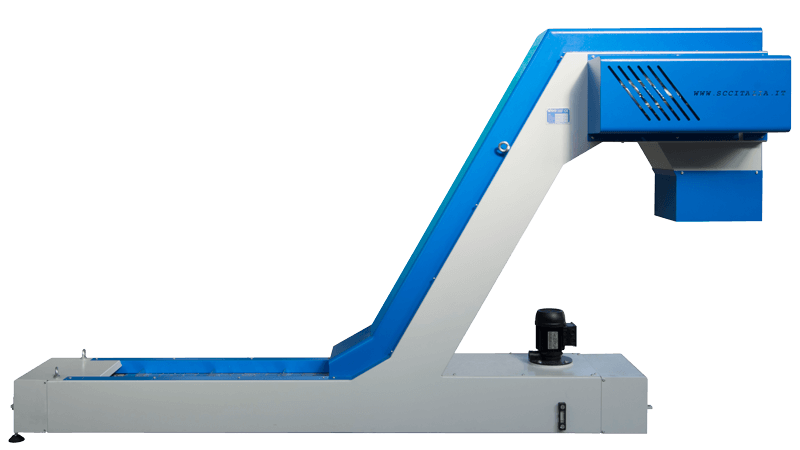

Dredging conveyor

Used for the transport of shredded or short curl chips.

The chips are coveyed by falling on the conveyor belt and removed by scraping palettes.

This solution is typically used in wet or dry processes, such as, for example, cast iron, brass and aluminum treatments.

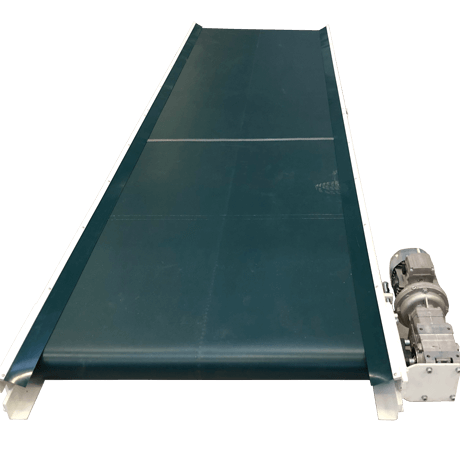

Rubberized conveyor

This type of conveyor is used for the moving of different materials, bulk and packaged ones, eco-friendly, electrical, agricultural, chemical, abrasives, food, mining products, etc.. with a wide range of models and accessories to ensure an effective performance under all conditions.

It consists of a conveyor belt pulled by two cylinders, one is motorized (motor drum) and the second ones is a transmission cylinder, both are mounted on steel shafts rotating on radial ball bearings.

The covers are made of different materials depending on the specific application, so you can get one solution:

- For food quality

- Resistent to oils and greases

- Heat-resistant

The belt can be closed in a loop that runs on a sheet metal plane, or on flat or trough idle rollers.

Conveyors on flat rollers

the belt has a flat shape with low sliding friction, even with high flow rates and very long, straight or curved spans, so enabling to increase the economic savings.

They are commonly used for the handling of packaged materials, even heavy ones.

Conveyors on trough rollers

The belt assumes a concave shape that can vary from time to time according to the rollers positioning, increasing the useful load capacity and the containment of the conveyed material. They are mainly used for bulk materials.

Harpoon conveyors

Harpoon conveyors are used for the removal of metal chips coming from the working process of high-chipping machine tools.

The liquid and the chips fall into the bed and are pushed at regular intervals by one oleodynamic handling system that transmits a reciprocating movement of “push and pull” to a series of modular dragging elements fixed by a sliding guide on the bottom of the bed.

On the sides of the bed there are located some tooth-shape elements with restraint function, which hold the chips during the return movement of the hydraulic cylinder, thus forcing them to advance at each thrust of the cylinder up to the collection point or in other systems.

SCC conveyor belt harpoon is a modular system

Generally mounted on the floor or buried and covered with metal sheet plates, with the exception of the entry points of the material to be moved.

It is suitable only for horizontal movements.

It is also possible to realize conveyors of outstanding length with a single drive command.

Centralizes the collection of chips, simplifying their management.

Recovers the cooling lubricant in a sump for re-use.

It allows continuous operation, intermittent or only in the presence of chips.

Riparazione e revisione dei nastri trasportatori

REPAIR AND OVERHAUL OF CONVEYOR BELTS

The process can include:

- Repair of damaged carpentry

- Repair and / or replacement of the metal belt

- Repair and / or replacement of the chain sliding guides

- Replacement of tow and idler sprockets

- Tow and neutral bearings replacement

- Painting of the carpentry

- Final testing of the repaired conveyor