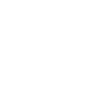

SCC offers bellows whose purpose is to protect the machine tools sliding guides and components against contamination of atmospheric and / or external agents (chips, dust, coolants, oils, etc.) and, as a result, they increase the working life of the same. Furthermore, they constitute an adequate protection against accidents.

SCC, attentive to the market he is working in, and ever projected towards the future, develops protective covers for mechanical parts that combine design and functionality, (protect and enhance the machine design), and are suitable for several applications. SCC bellows are used in many industries, such as: machine tools, machines for processing marble, wood, industrial automation, etc.

SCC BELLOWS COVERS DISTINGUISH THEM FOR:

- Simple construction

- High quality of selected materials

- High travel speed

- Minimum closed pack

- Easy assembly

- Versatility and Modularity: products compatible with the most varied work axes and related production processes

- Protects and improves the machine design

SCC, thanks to its know-how, is able to understand the customer needs providing his full support from the early stages of the project, offering the most appropriate solution for its future use. If the standard production models did not comply with the customer needs, SCC is able to offer highly customized solutions and, again, to develop new “ad-hoc” projects from scratch. Each product is manufactured with the utmost care and carefully checked by our quality department before delivery.

Also, we guarantee short delivery time and assistance, upon request, of our staff highly specialized in the installation of this product.

-

TECHNOLOGY

- Thermowelded

-

DESCRIPTION

- Made by heat-sealing the door on support frames (no adhesives).

-

APPLICATION

- Solution resistant to mechanical stress and watertight.

-

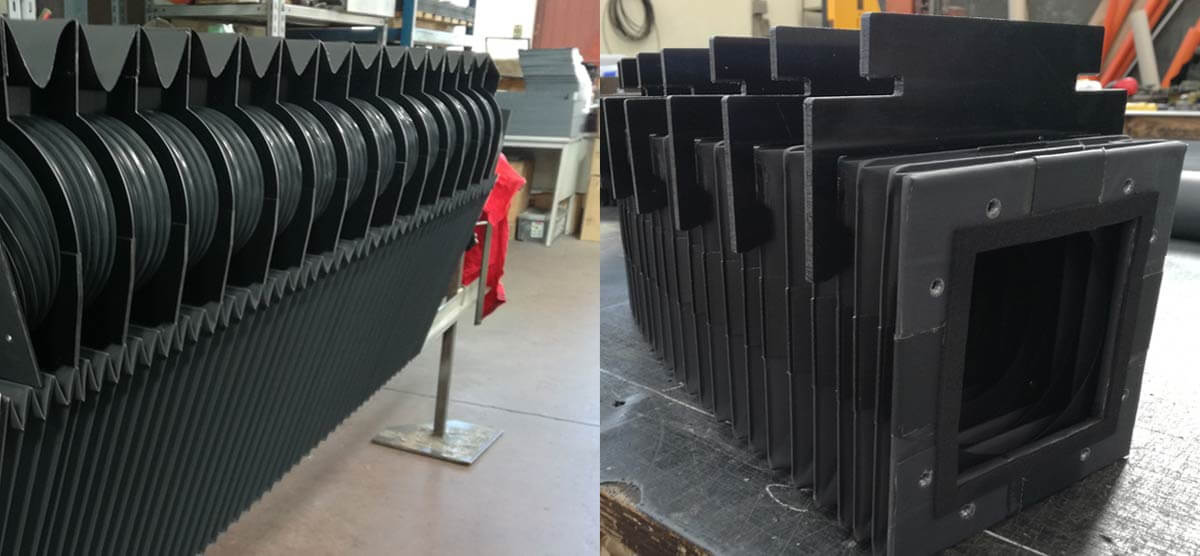

TECHNOLOGY

- Lamellar welded

-

DESCRIPTION

- Heat-welded execution with the application of stainless steel slats fixed on each fold of the mantle. The slats can be oscillating or fixed.

-

APPLICATION

- Solution resistant to mechanical stress and watertight. Protection from hot chips, welding sprays and sparks.

-

TECHNOLOGY

- Heat sealer

with pantograph -

DESCRIPTION

- Welded execution with internal metal bearing structure (pantograph).

-

APPLICATION

- Solution resistant to mechanical stress and watertight.

-

TECHNOLOGY

- Stitched

-

DESCRIPTION

- Made by stitching with nylon or kevlar thread of rings in material selected according to the application.

-

APPLICATION

- Solution resistant to coolants. No watertightness.

-

TECHNOLOGY

- glued

-

DESCRIPTION

- Made by gluing the door onto PVC frames.

-

APPLICATION

- Solution that does not require guides, but is self-sustaining.

MATERIALS

The bellows can be constructed in different materials, designed for

different physical and chemical stresses to which they will be subjected. Details on this are shown in the following table.

| MATERIAL | THICKNESS | HEAT RESISTANCE | FABRIC RESISTANCE | ||

|---|---|---|---|---|---|

| OUTSIDE SIDE | TEXTILE INSERT | INTERNAL SIDE | (mm) | Min ° / Max °c | |

| Silicone | Glass fiber | PVC | 0,44 | -30 / +200 | Self-extinguishing. Resistant to dust, acids and splashes of coolant. |

| Polyurethane | Polyester | Polyurethane | 0,25 / 0,35 | -30 / +90 | Self-extinguishing. Resistant to petroleum products, oils, acids and grinding dust. |

| Polyurethane | Aramid | Polyurethane | 0,45 | -30 / + 380 | Self-extinguishing. Excellent mechanical resistance. Resistant to petroleum products, abrasions and welding splashes and incandescent materials. |

| PVC | Polyester | PVC | 0,25 / 0,36 | -30 / +70 | Self-extinguishing. Resistant to dust, oils and coolants. |

| PVC | Polyester | PVC | 0,40 | -30 / +70 | Self-extinguishing. Fireproof. Resistant to welding splashes and shavings. |

| Polyurethane | Kevlar | Polyurethane | 0,36 | -30 / +180 | Self-extinguishing. Excellent mechanical resistance. Used in laser cutting machine. |

| Note: Material supports: PVC |

Connection flange material: Steel, Aluminum, PVC |

Slat material: Stainless steel |

|||

BELLOWS FOR LASER AND PLASMA

SCC is highly specialized in the production of thermo-welded (heat-sealed) bellows made of high quality flame retardant and self-extinguishing materials for use in laser and plasma cutting machines (guiding and pinion).

INNOVATIVE SOLUTIONS CUSTOMIZED

SCC produces bellows that combine design and functionality and are suitable for the most various fields of application, even the most difficult. The modern machine tools employ advanced engines and technologies that allow very high speeds and accelerations. For these reasons, the protection of machine sliding guides and transmission parts becomes difficult with traditional products. Thanks to its tools and experience, SCC exploits the versatility of the bellows to realize innovative solutions for the most difficult applications, ensuring the satisfaction of the most demanding customers.