SCC designs and manufactures systems for the purification of lubricating and cooling liquids for machine tools. This products range consists of different models of purifiers that by adopting different technologies, allow to face and solve the problem of the filtration of lubricants in all its aspects.

All these series also include the design &manufacturing of customized solutions and, if required, ad-hoc products designed to meet more and more refined customers.

SELF-CLEANING DRUM FILTRATION SYSTEM-FAT SERIES

The FAT series is a self-cleaning rotary drum filtration system designed for the separation and removal of magnetic or non-magnetic particles from neat oils or emulsions, specifically designed for those plants that require high capacity solid / liquid separation systems.

It is available in different models capable of handling up to 500 l / min of neat oil and 1000 l / min of emulsion, with a filtration system completely customizable, and allows the differentiated disposal of the waste without the use of consumable filtration materials

Moreover, the drum filtering cylinder is self-cleaning, as it is equipped with a system of washing nozzles, thus allowing the maintenance reduction of the equipment itself.

To solve the problem of the filtration of the cooling lubricants and, thus, maximize the productivity of the same manufacturing process, in addition to the standard production models, SCC is able to provide customized solutions.

Application

Our series of self-cleaning drum filters is used in all chip removal machine tools, such as:

- Machining Centres

- Transfer

- Lathes

- Rectifying And Deep Boring

- Other Heavy Manufacturing Processes

Main sectors the rotary drum filter is generally used in:

- Mechanical and automotive industry, where there are manufacturing processes that involve the removal of chips by washing, abrasion process, etc.

- Sewage treatment and waste water treatment plants for various separation processes of solids from waste water

- Plastic chemical industries: paints, solvents, tanneries, etc.

- Beverage industries: distilleries, cellars, breweries, etc.

- Food industries

Operation

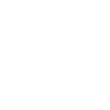

The polluted liquid is conveyed inside the purification system by pumps in the sleeve (b) placed above the filter and from here, thanks to the principle of communicating vessels of archimedes, it crosses the wire mesh placed on the rotary drum (a) passing through the drum and depositing the pollutant particles which contains on the outer side of the drum mesh itself. Until the layer of polluting particles deposited on the filter mesh is able to allow the constant flow of liquid passing through the drum, the levels remain equal and the dirty liquid coming from the outside continues to cross the metallic mesh, purifying itself from impurities.

The polluted liquid is conveyed inside the purification system by pumps in the sleeve (b) placed above the filter and from here, thanks to the principle of communicating vessels of archimedes, it crosses the wire mesh placed on the rotary drum (a) passing through the drum and depositing the pollutant particles which contains on the outer side of the drum mesh itself. Until the layer of polluting particles deposited on the filter mesh is able to allow the constant flow of liquid passing through the drum, the levels remain equal and the dirty liquid coming from the outside continues to cross the metallic mesh, purifying itself from impurities.

As the filter mesh gradually gets dirty, when the coolant reaches the maximum internal level allowed, a self-cleaning cycle is started automatically. In fact n° 2 sensor levels, installed into the fat system and duly protected by dirt to prevent any signal alteration, send a command to the dredging system (d) and the drum that starts to rotate in order to expose a new clean portion of the wire mesh so that to restore the balance of the liquids.

After the rotation phase, the filter mesh section clogged with the sludge is no longer immersed in the liquid and is in a stand-by position, while a double cleaning system (c – e) cleans it perfectly and make it permeable again for the subsequent filtration cycle.

The sludge that detaches from the drum mesh is gathered at the bottom of the purification system, where a dredging system (d) discharge the same outside. Each dredger before returning into the filtration cycle is in turn cleaned up by a system of cleaning (f) so ensuring its perfect operation.

Technical charachteristics

Our range of self-cleaning drum filters consists of 6 standard models for the purification of lubricating and cooling liquids, i.e. neat oils and emulsions, with a maximum viscosity of 20 ° cSt at 40 ° C contaminated.

Main technical characteristics:

- Flow rate from 200 to 1000 liters / minute of emulsified oil (value reduced to 50% in case of neat oil).

- Filtration rating from 50 to 150 microns (averaged value)

- The drum is entirely made of 304L stainless steel.

- The filter consists of a wire mesh profile also made of 304L stainless steel.

- Complete system of electrical absorption to protect against overloads.

- The SCC drum filters can also be supplied complete with accessories and additional options as requested by the Customer (see “Types” section).

Types

The FAT series produced by SCC is available in the following models:

| TYPE | EMULSION CAPACITY L/MIN | PORTATA OLIO L/MIN | BATHTUB VOLUME | A | ENTRANCE |

|---|---|---|---|---|---|

| FAT-200 | 200 | 100 | 800 | 600 | 3″ |

| FAT-300 | 300 | 150 | 1200 | 700 | 3″ |

| FAT-400 | 400 | 200 | 1600 | 800 | 3″ |

| FAT-600 | 600 | 300 | 2400 | 900 | 4″ |

| FAT-800 | 800 | 400 | 3200 | 1100 | 4″ |

| FAT-1000 | 1000 | 500 | 5000 | 1300 | 4″ |

Additional components

Our technical department is always available to identify and develop the most suitable solution to meet the specific needs of the customer.

Optional

SCC drum filters can be supplied, upon specific customer request, complete with additional options, custom designed:

- Additional tangential washing

- Dredge unit cleaning system

- Backwashing pump (two available models)

- Cartridge filters or pressure switch for self-management functioning of

backwashing PLC (Programmable Logic Controller)

Maintenance

The design, the components and the related materials used make the filtering system with a rotating drum almost maintenance-free.

They only need to provide spare parts for some components of the equipment, such as the segments with filtering net to be replaced. in case of breakage.

MAGNETIC SEPARATION SYSTEM–DPM SERIES

SCC designs and manufactures purification systems for lubricating and cooling liquids for machine tools. The DPM series consists of various types of purifiers that enable to face and solve the problem of the filtration of coolants in all its aspects.

The SCC magnetic separation system consists of a rotating steel discs magnetic separators suitable for the removal of magnetic particles from neat oils and emulsions.

It is available in different models capable of treating up to 250 l / min of neat oil and 500 l / min of emulsion, allowing the differentiated waste disposal.

In addition to the standard models of our production range, thanks to his specific know-how, SCC is able to offer customized solutions and also develop new projects from scratch specifically for the customer.

Application

Our rotating discs magnetic separators for lubricants and coolants can be used in all chip removal machine tools, such as:

- centralized systems

- machining centre

- lapping machines

- transfer

- lathes

- boring machines

- sharpening machines

- broaching machines

- grinding and deep boring machines

- other heavy manufacturing processes.

Operation

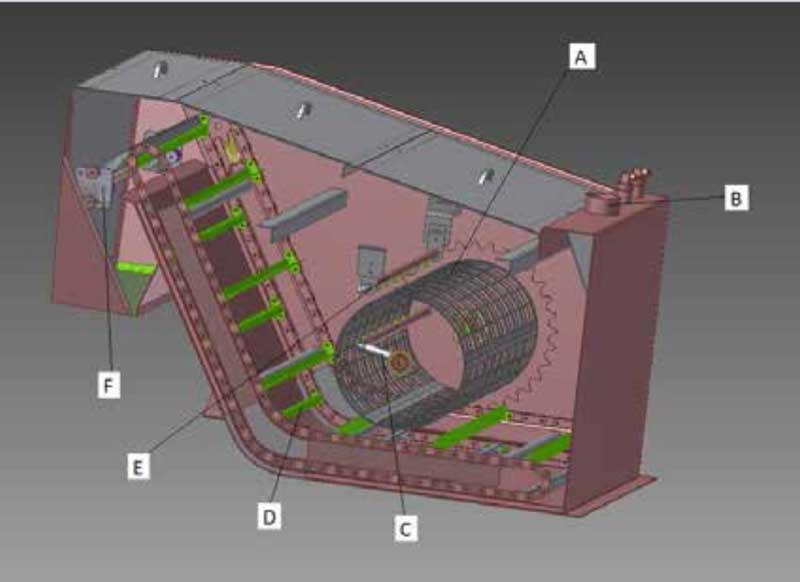

The contaminated coolant, conveyed inside the separator by gravity or through pumps via a sleeve (F) or through a flow-breaking chamber (G), passes through one nozzle (E) and the group of rotating magnetic discs (A) (H), where the magnetic particles are captured. These are hence removed by a special scraping – blade, in AISI 304, (B) conveying the sludge to the variable inclination chute (C) so allowing to control the recovery of liquids.

The clean liquid passes into the tank (D) and subsequently, depending on its use, is pumped in back to the machine tool by a dedicated pump. The magnetic disc separation system does not use consumable filter media and enables an easy differentiated disposal of the recovered sludge.

Technical characteristics

This system is used for the purification of coolants, i.e. neat oils and emulsions, with a maximum viscosity of 20 ° cSt at 40 ° C contaminated by magnetic particles. Our range of magnetic separators is made up of 8 standard models and through the application of rotating magnetic disks is able of purifying from 50 to 500 liters / minute of emulsion and from 25 to 250 liters / minute of neat oil. The SCC magnetic separtors can also be supplied with accessories and additional options, also custom-designed according to specific client demand (see “Types”).

The rotating disc magnetic separation system does not use consumable filtration materials and allows the differentiated industrial waste disposal

Types

The series of magnetic purifiers produced by SCC is available in the following models:

| TYPES | LITERS | A | B | C | EMULSION CAPACITY L/MIN | OIL CAPACITY L/MIN | |||

|---|---|---|---|---|---|---|---|---|---|

| DPM50 | 50 | 184 | 384 | 3″ | 50 | 25 | |||

| DPM100 | 100 | 255,2 | 455,2 | 3″ | 100 | 50 | |||

| DPM150 | 150 | 362 | 562 | 3″ | 150 | 75 | |||

| DPM200 | 200 | 433,2 | 633,2 | 3″ | 200 | 100 | |||

| DPM250 | 250 | 504,4 | 704,4 | 3″ | 250 | 125 | |||

| DPM300 | 300 | 646,8 | 846,8 | 3″ | 300 | 150 | |||

| DPM400 | 400 | 860,4 | 1060,4 | 3″ | 400 | 200 | |||

| DPM500 | 500 | 1002,8 | 1202,8 | 3″ | 500 | 250 | |||

| Note: The nominal flow data shown in the table refer to an emulsion with a maximum oil concentration of 5% or whole oil with a maximum viscosity of 20cst at 40 ° C. | |||||||||

Additional components

Different characteristics of the liquid to be treated, of the type of pollutant and its concentration can considerably affect the performance of the purifier. Our technical department is at full disposal to identify and develop the most appropriate solution to meet the specific needs of the customer.

Options

SCC magnetic separation system can be supplied upon specific customer request complete with:

- Electrical cabinet

- Pre-chamber breakwater

Maintenance

The simple construction, the components and the relative materials used make the SCC purifier almost maintenance-free. It is only needed to provide the spare parts for some components of the equipment .

Magnetic separation system with permanent magnetic bars - MFP SERIES

The permanent magnetic separation system is used for the liquid coolants filtration of magnetic metals machining processes. This system is made up of some permanent magnetic cylindrical bars for ultrafine separation of ferrous materials from cooling lubricants, grains, plastic granules, flour, etc.

Thanks to its structure in stainless steel 304 or 316, it is also suitable for the separation of magnetic material from food products. Moreover it offers the maximum design flexibility and high performances.

In a market increasingly attentive to the environmental impact of processes, products and services, the following features of the permanent magnetic separation system make it stand out:

- Simple, robust and reliable construction

- Ferrite or Neodymium magnets not affected by magnetism

- Maximum contact surface

- Flexibility: applicable to all machine tools

- No consumable filters

- Reduced economic investment

- Reduced dimensions

- Easy installation

- Upgradeable magnetic efficiency to fulfill the project requirements

Application

The permanent magnetic separation system is used in the most varied applications, starting from the simplest to the mounting in different machines tools. The permanent magnetic separator can also be used in the mechanical industry, in the construction of equipment, in bioengineering, in the textile industry, in aeronautical and aerospace engineering and in the food industry.

In particular in the machine tool industry, they are widely used in all chip removal machines, such as:

- Centralized systems

- Work centres

- Lathes

- Industrial sawing machines

- Grinding machines

- Other heavy machining processes

Operation

The permanent magnetic separation system, used in the filtration of ferrous scraps during the passage of coolants in hoppers or tanks, is based on the magnetic field conveyance principle. It enables to get a very strong magnetic flux near the pitch between the magnetic steel bars.

Technical features

Structure in 304 or 316 stainless steel. The magnetic grid in standard configuration is made up of 5 magnetic cylindrical bars. Inside the cylinders, Ferrite or NdFeB magnets can be inserted depending to the specific need and the required filtering capacity. The magnetic cylinders can be fixed directly on customer supports by means of the threaded arrangement at the ends of the same, or they can be mounted in series or grid configuration to obtain different filtration capacity.

Maintenance

The simple construction and the applied materials make the permanent magnetic separator almost maintenance-free. The cleaning operations consist in slipping the single magnetic bar from its seat for the removal and subsequent disposal of the polluting sludge.

MACHINE TOOL OIL SEPARATORS DAN SERIS – DAD SERIES

SCC designs and produces two types of oil separators for the treatment of oily emulsions and coolants, capable of separating oil in continuous cycle, compact, versatile and of high quality, ensuring many advantages both economically and environmentally. The use of these systems allows to evacuate in a short time only extraneous oils from the machining process liquid, so minimizing the scrap volumes to be removed. This process allows the reduction of bacterial charges and the complete elimination of smokes and foul odors caused by the presence of fungi/light products floating in the tanks of the machine tools, so enabling to preserve the coolants quality longer.

SCC oil separators, thanks to their design and high quality materials, have the prerogative of being versatile. In fact, within a production process, the same system can be used for several machine tools, guaranteeing different advantages.

They can also be used on any type of tank or basin, even in the presence of basin that are underground or with limited accessibility.

In order to effectively respond to every need for oil separation, SCC offers two different types of oil separators:

oil separators belt version – DAN SERIES

oil separators disc version – DAD SERIES

Each series is available in various models to best solve the problem of the pollution of coolants and, consequently, obtain:

- A significant reduction in costs

- The reduction of the frequency of renewal or reinstatement of the emulsions / cooling lubricants

- The reduction of disposal costs

- Maggiori tempi di funzionamento degli impianti

- More plant operation time

- No need for additional filtration material (additives, etc.)

- Compliance with environmental regulations in force

In addition to these standard products, SCC is able to supply custom-made oil separators and on specific client requirements. The SCC oil separators can be completely integrated with the self-cleaning drum systems of our production.

Application

Our series of oil separators is generally used in a wide range of sectors, such as the automotive, chemical, paper and steel industries, heat treatment departments, die-casting and aluminum foundries, the petrochemical mechanical industry and refinery service stations, train and aircraft repair companies as well as the food industry.

The main industrial processes they are commonly used are:

- Centralized systems

- Machining centres

- Lapping machines

- Transfers

- Lathes

- Boring machines

- Sharpening machines

- Broaching machines

- Deep grinding and boring machines

- Other heavy machining processes

Application

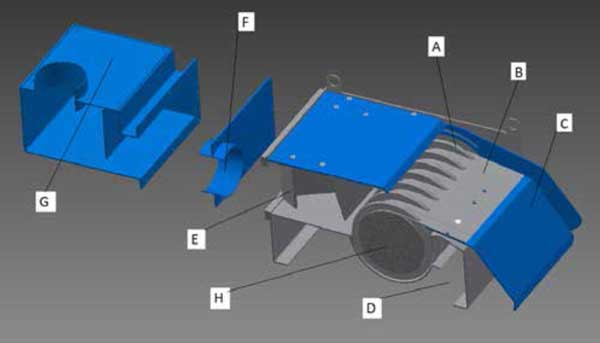

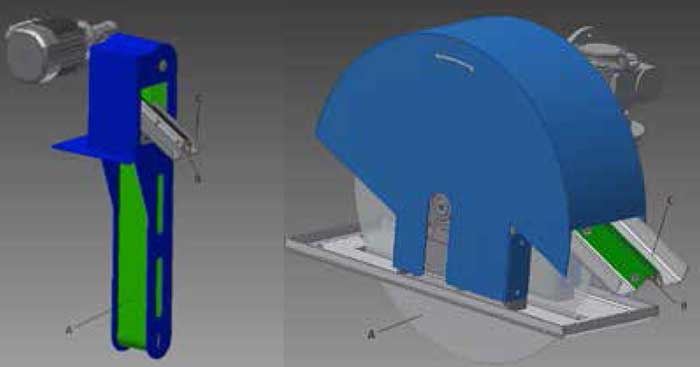

The disc / belt (A) is immersed into the liquid and through its rotation the pollutants adhere to its surface and are dragged out.

In its rotation, the disc / belt meets two scrapers (B) fitted with a rubber rim which remove everything that stuck to it and convey the same outside through proper exit ducts (C). The oil separator can be supplied complete with one electrical control panel with the possibility of setting up temporized operating cycles.

Features

- Compact equipment layout, limited weight and small overall dimensions

- Versatility, oil separator suitable for any type of machine tool

- Easily transferable between machining workstations

- Increased life of tools and emulsions / cooling lubricants

- Reduced disposal costs and flora bacteria

- Ease of use and reduced cleaning times

- Manual or automatic mode of operation

Maintenance

all SCC detectors are distinguished not only for their versatility, but also for their easy maintenance.

The extremely simplified design of these products means that maintenance is limited to the periodic inspection of scrapers, subject to wear, and to the cleaning of the exhaust ducts to keep the entire oil separation system efficient and highly performing.

OIL SEPARATION SYSTEM – BELT VERSION – DAN SERIES

The DAN series is used where there is little space available and in the presence of high excursions of the coolant liquid level. The main features and types are shown in the table.

| TYPE | A | B | C | D | L | MAXIMUM OIL EXTRACTION L/H |

|---|---|---|---|---|---|---|

| DAN-210 | 260 | 290 | 90/120 | 270 | 210 | 6-15 |

| DAN-410 | 260 | 290 | 90/120 | 270 | 410 | 6-15 |

| DAN-610 | 260 | 290 | 90/120 | 270 | 610 | 6-15 |

The DAN series by SCC is available in the following

The DAN series by SCC is available in the following

| TYPE | A | B | C | D | E | F | G | H | I | L | M | N | O | MAXIMUM OIL EXTRACTION L/H | WEIGHT Kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DAD-350 | 350 | 400 | 150 | 60 | 50 | 120 | 260 | 300 | 80 | 462 | 374 | 66 | 13 | 13 | 15 |

| DAD-500 | 600 | 550 | 150 | 52 | 28 | 120 | 260 | 300 | 180 | 612 | 524 | 66 | 13 | 22 | 18 |

| DAD-600 | 600 | 650 | 150 | 78 | 0 | 120 | 260 | 300 | 230 | 740 | 624 | 66 | 13 | 35 | 20 |